NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

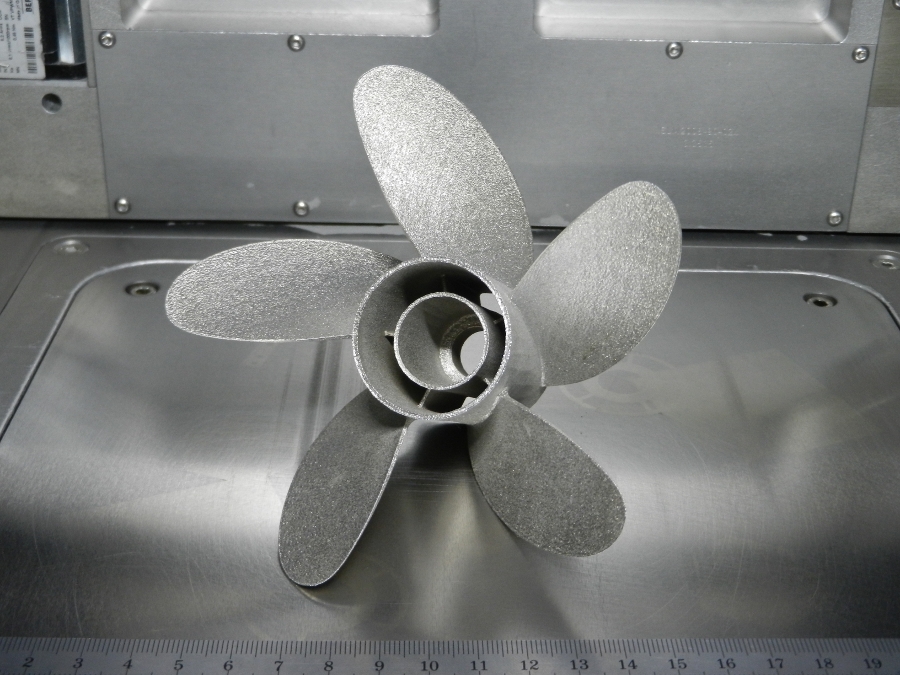

ET-S200 Metal 3D Printer / Additive Manufacturing (AM) System Specifications

- Model: ET-S200

- Product description: ET-S200 Metal 3D Printer / Additive Manufacturing (AM) System Specifications

Product introduction

1.Main Specifications:

|

Laser |

Type |

YLR-SM Single-mode |

|

wavelength |

1070nm |

|

|

Beam Quality |

M2≤1.1 |

|

|

Power control |

Continuous/pulse |

|

|

Nominal Output Power |

200W |

|

|

Laser cooling mode |

Cooling machine circulation water(with Water shortage self-protection, flow, pressure alarm function) |

|

|

Cooling Water Power |

1.5 HP,±0.5℃ |

|

|

Optical path and scanning system |

Focal plane spot |

80-100µm |

|

Scan system |

High speed and high precision focal plane Germany f~θ lens |

|

|

Scanning speed of vibration mirror |

6m/s |

|

|

Max scan speed |

7m/s |

|

|

optical path director |

The laser comes with red light |

|

|

Control System |

IPC |

YanHua |

|

Windows 7 |

||

|

MCS Professional control software |

||

|

Motion System |

high precision servo motor control, forming cylinder positioning accuracy±5μm。 |

|

|

Software |

MagicsRP、Magics SG+ Slice and support generation software SLM scan path plan BP software SLM forming control MCS software |

|

|

Forming Chamber |

Building volume(mm) |

105mm×105mm×200mm; |

|

Layer thickness |

20µm-100µm; |

|

|

metal material |

Titanium alloy, stainless steel, aluminum alloy, high temperature alloy, etc |

|

|

Protect Gas System |

Inert gas flow |

inert gas regeneration and flow control |

|

Oxygen contents |

≤100ppm |

|

|

Sealing mode |

Integral sealing |

|

|

Forming System |

Protect gas |

Argon |

|

Max gas consumption |

100L/min |

|

|

Max power |

15KW |

|

|

Power |

380V |

|

|

Position accuracy |

±0.005mm/full process |

2. Laser Parameter

|

Characteristics |

Parameters |

Notes |

|

Power |

200W |

|

|

wavelength |

1060nm-1080nm |

|

|

Power instability |

±1%-±3% |

|

|

Response Time |

30-50μs |

|

|

Beam Quality |

M2:1.05-1.1 |

|

|

Beam Divergence |

0.3-0.5mrad |

|

|

Switching ON/OFF |

30-50μs |

|

|

Red Guide Laser Power |

1mW |

|

|

Delivery Fiber Length |

5m |

|

|

Delivery cable Bending Radius |

50mm |

|

|

Operating Ambient Temperature Range |

10-50℃ |

|

|

Humidity |

10%-90% |

Difference humidity according to the room temperature |

|

Working voltage |

200V-240V |

|

|

Dimensions |

448mm×580mm×132mm |

|

3. Specification for Two-dimensional scanning mirror

|

Item |

Parameter |

Remark |

|

Marking speed |

1.0m/s |

|

|

Positioning speed |

11.0m/s |

|

|

Tracking error |

0.32ms |

|

|

Typical scan angle |

±0.35rad |

|

|

Power requirements |

30V DC |

Max 6A |

|

Response time |

10%:1.9ms |

|

|

Repeatability |

<0.4μrad |

|

|

Positioning accuracy |

0.82μrad |

|

|

Writing speed/frequency |

340-230cps |

|

|

Operating temperature |

25℃±10℃ |

|

|

Cooling water flow |

5L/min P<4bar |

|

|

Compressed air flow |

20L/min |

Differential pressure is less than 2bar |