NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

Full Automatic High Vacuum Thermal Evaporation Coating System ET-EVAP400C-1

- Model:ET-EVAP400C-1

- Product description: Full Automatic High Vacuum Thermal Evaporation Coating System ET-EVAP400C-1

Product introduction

Main Specification

|

Model |

ET-EVAP400C-1 |

||

|

Ref. Pictures |

|

||

|

Main Vacuum Chamber |

Rectangle 304 Stainless steel chamber, Size: 400mm×400mm×450mm. The front door is full auto control (integrated with glove box), the outside door is hinged type for service. The two doors are provided with an observation window. The chamber is provided with a lighting and film thickness instrument and another equipment interface.

|

||

|

Vacuum System |

Pumping by turbo-molecular pump (pumping speed 1200L/S) + Joint venture direct coupling rotary vane pump (pumping speed 9L/S), high vacuum electro-pneumatic valves, full automatic control |

||

|

Ultimate Vacuum |

≤6×10-5Pa |

||

|

Pumping Speed |

Pumping from air to 9×10-4Pa≤30min(short time expose in the air, feeding dry Nitrogen, then starting vacuum) |

||

|

Substrate system |

Sample Size |

Drawer type structure, carrying a maximum of less than 120 x 120mm samples, equipped with Japan SMC pneumatic substrate baffle, electrical linkage fully automatic control |

|

|

Moving Mode |

• The substrate table adopts the magnetic fluid seal, which can be lifted and lifted, and the distance between the source and the substrate can be adjusted continuously by 200~300mm.; • The substrate table can rotate continuously, and the rotating speed is 0~30 • Above processing are full auto control |

||

|

Heating |

Room temperature ~300℃, Japan SHIMADEN PID intelligence temperature control system |

||

|

thermal source |

Metal Thermal Source |

2units, Water cooling pure cooper electrodes+ thermal boat |

|

|

Organic Thermal Source |

sing PID temperature organic beam source furnace, the crucible is larger than 2CC, room temperature of ~300 ℃, continuously adjustable |

||

|

Thermal power |

Metal Thermal Power |

Current 300A, maximum output power 3KW(Conversion for two sets of alternating evaporation) |

|

|

Organic Thermal Source |

PID Intelligent temperature controlled evaporation power supply (temperature control accuracy±1℃) |

||

|

Coating Thickness Control System |

The quartz crystal film thickness controller, monitoring the thickness of the display range: 0-99μ9999Å |

||

|

Water Cooling System |

Equipped with cooling water circulation machine, the user only need to provide the site |

||

|

Alarm & Protect System |

Perfect logic program interlock and protection system, the pump, electrode and other water shortage, over current over-voltage, open circuit and other abnormal alarm and the implementation of the corresponding protection measures |

||

|

Coating thickness non-uniformity |

Φ100mm≤±5.0% |

||

|

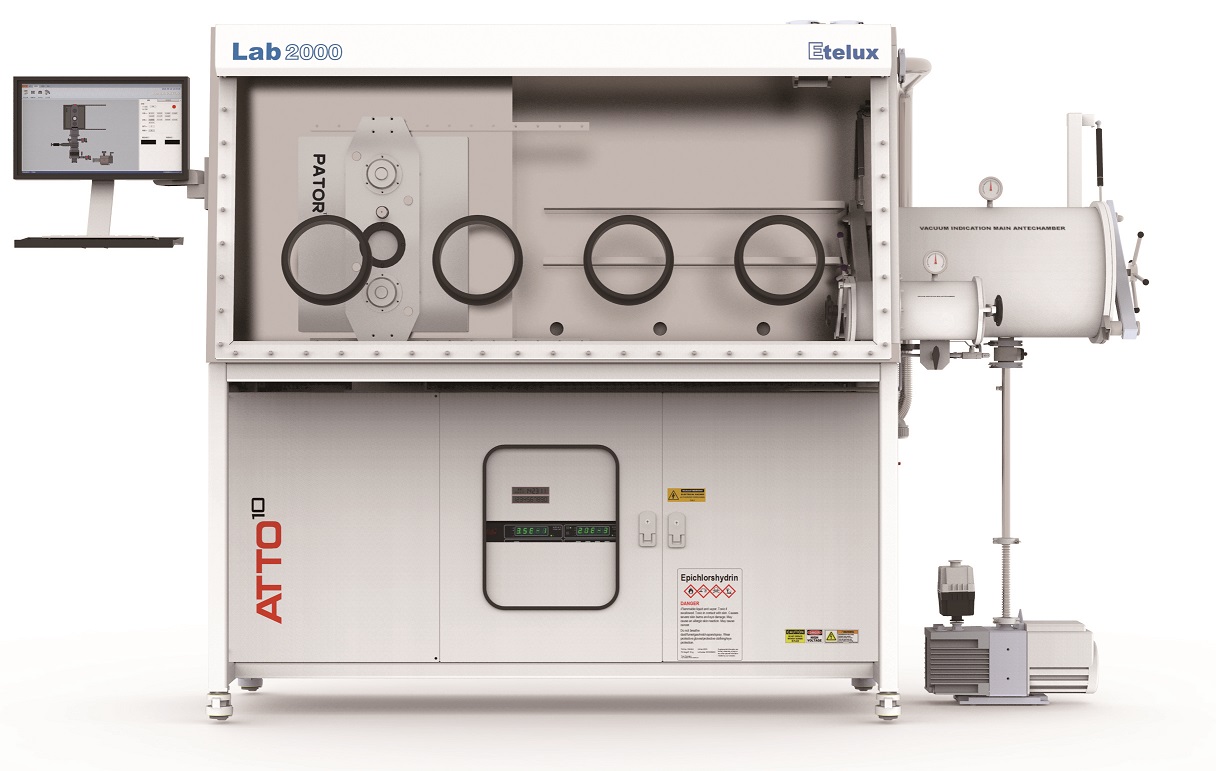

Glove box System |

Glove Box chamber |

Chamber size: 1500×750×900mm Main antechamber:¢360×600mm,mini-chamber: ¢150×300mm Height of stand: 950mm |

|

|

Gas purify System |

Moisture & oxygen <1ppm Single Column Purification System Solvent Purification System GE US brand moisture & oxygen analyzer |

||

|

Control mode |

PLC+PC full auto control |

||