NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

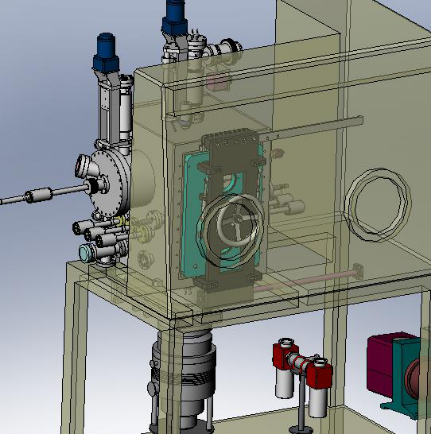

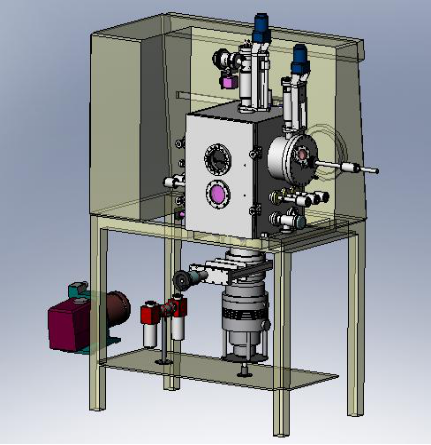

Glove box system & High-vacuum resistance thermal evaporation coater,Deposition & Metallization System up to 100mm x 100mm Substrate

- Glove box system

- High-vacuum resistance thermal evaporation coater

- Organic Thin Film Deposition

- Metallization System

- Product description: Glove box system & High-vacuum resistance thermal evaporation coater,Deposition & Metallization System up to 100mm x 100mm Substrate

Product introduction

|

||

|

Glove box system |

||

|

Description |

|

|

|

Volume |

|

|

|

Front window |

|

|

|

Glove ports |

|

|

|

Gloves |

|

|

|

Filter |

|

|

|

Lighting |

|

|

|

Leak rate |

|

|

|

Single-column gas purification system (two sets) |

||

|

Description |

|

|

|

Voltage |

|

|

|

Working gas |

|

|

|

Vacuum pump |

|

|

|

Circulation unit |

|

|

|

Valve |

|

|

|

Leak rate |

|

|

|

Control cabinet dimensions |

|

|

|

Transfer chamber |

||

|

T-type large transfer chamber |

Material |

|

|

Dimensions |

|

|

|

Vacuum level |

|

|

|

T-type small transfer chamber |

Material |

|

|

Dimensions |

|

|

|

Vacuum level |

|

|

|

Large transfer chamber |

Material |

|

|

Dimensions |

|

|

|

Vacuum level |

|

|

|

Small transfer chamber |

Material |

|

|

Dimensions |

|

|

|

Vacuum level |

|

|

|

Puring system |

||

|

Description |

|

|

|

Analyzer |

||

|

O₂ analyzer |

Dimensions |

|

|

Measurement range |

|

|

|

Other oxygen analyzers |

|

|

|

H₂O analyzer |

Dimensions |

|

|

Measurement range |

|

|

|

Other moisture analyzers |

|

|

|

Solvent purification system |

||

|

Description |

Casing material |

|

|

Internal dimensions |

|

|

|

Filling material |

|

|

|

Optional equipment |

||

|

Low-temperature freezer |

Temperature |

|

|

Volume |

|

|

|

Structure |

|

|

|

Material |

|

|

|

Refrigerant |

|

|

|

Heating chamber |

|

|

|

Modular Process Chamber |

||

|

Dimensions |

|

|

|

Material |

|

|

|

Volume |

|

|

|

Observation window |

|

|

|

Ultimate vacuum |

|

|

|

Vacuum recovery |

|

|

|

Interface |

|

|

|

Lighting |

|

|

|

Lighting |

|

|

|

Vacuum system |

||

|

Description |

|

|

|

Pumping speed |

|

|

|

Vacuum pump |

Specifications |

|

|

Flow rate |

|

|

|

Vacuum level |

|

|

|

Operating voltage |

|

|

|

Pumping speed |

|

|

|

Valve |

Main valve |

|

|

Foreline valve / Bypass valve |

|

|

|

Vacuum measurement |

|

|

|

Sealing |

|

|

|

Substrate holder |

||

|

Description |

|

|

|

rotation |

|

|

|

lifting |

|

|

|

masking |

|

|

|

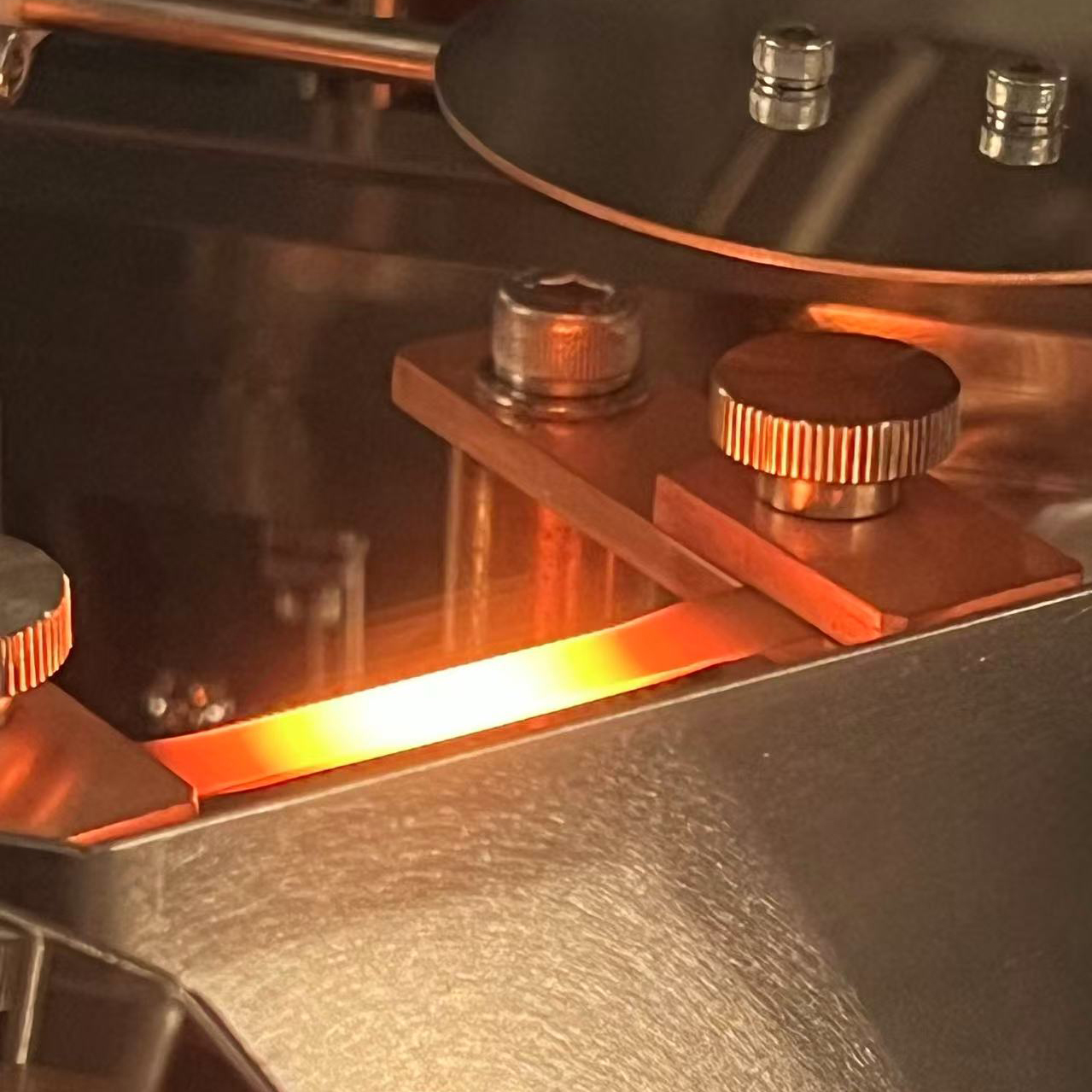

Evaporation source |

||

|

Evaporation source |

Structure |

|

|

Evaporation temperature |

|

|

|

Evaporation source |

Output power |

|

|

Control |

|

|

|

Quantity |

|

|

|

Control system |

||

|

Description |

|

|

|

Features |

|

|

|

Film thickness monitoring and control system |

||

|

Description |

|

|

|

Range |

|

|

|

Features |

|

|

|

Water cooling system |

||

|

Description |

|

|

|

Optional equipment |

||

|

Substrate holder |

Heating |

|

|

Water cooling |

|

|

|

Liquid nitrogen cooling |

|

|

|

Liquid nitrogen cooling |

|

|

|

Liquid nitrogen cooling |

|

|

|

Stepless tilting and rotation |

|

|

|

Vacuum baking/degassing |

|

|

|

Sample loading chamber |

|

|

|

Chamber heating |

|

|

|

Water cooling system |

|

|

|

Other specifications |

||

|

Product certification |

|

|

|

Warranty period |

|

|

|

Application notes |

|

|

|

Packaging dimensions(W×D×H) |

|

|

|

Weight |

|

|