NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

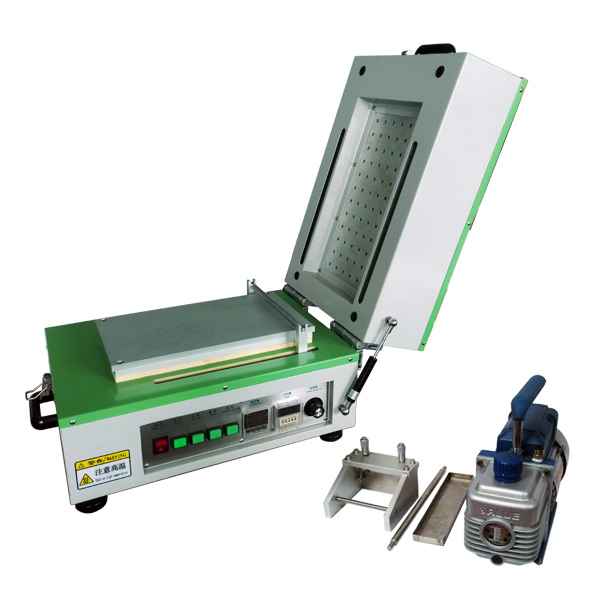

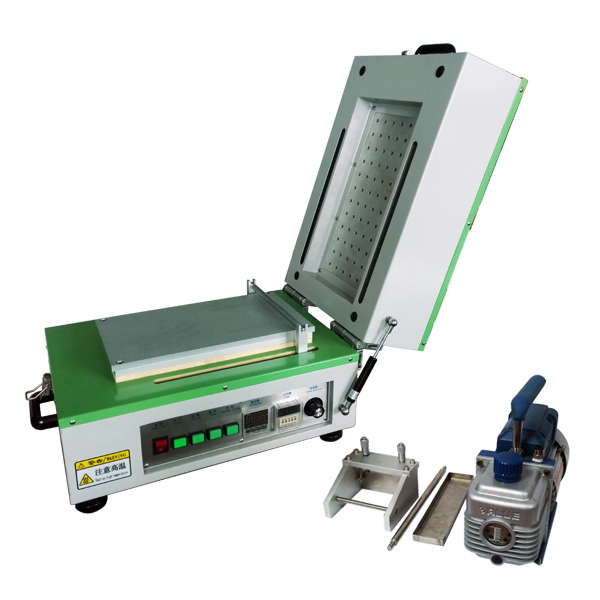

YD-01250 Automatic Film Coater With Dryer

- Product description: YD-01250 Automatic Film Coater With Dryer,Glovebox

Product introduction

|

Picture |

|

|

Introduction |

It applies in wide variety of high temperature filming coating research, such as Ceramic film, crystal film, cell material film, special nano film;It can adapt to the film formation under the high temperature in the future with the development of science |

|

Main features |

- The wind loop dryer heater, digital display temperature control, Max. Heating Temp.: 200°C - Digital display timer can be set drying time freely

- adjustable traverse speed from 0 to120mm/sec |

|

Specification |

- Traverse speed: 0~120mm/Sec; - Stroke Length:0~250mm adjustable by using Adjustable Position Switch

- Vacuum chuck:Aluminum alloy flat vacuum chuck

- Included oil-free vacuum pump: one set - Dimension:L500mm×W350mm×H320mm;(19.7in×13.8in×12.6in) - Weight:50KG; |

|

Standard accessories |

Micrometer level adjustable film coating device,width:100mm |

|

Operation process |

(1).put the electrode sheet. On the vacuum chuck, start power, open vacuum then the electrode sheet is adsorbed on the vacuum chuck (2). Put the coater on the electrode sheet, put in coating slurry; (3).Open coater for auto coating (4).dry the films and remove binder after coating; cover heating lid, set the heating temperature and drying time (5).Drying is completed, open lid, remove the electrode coating, the coating device reset is completed; |

|

Maintenance notice |

1.clean with soft clothes dip with alcohol before using 2. The coating head, high precision parts using differential is not collision, gently,adjust Differential device need Symmetrical even 3.Regularly checking each parts, such as Screw, nut, pin.Avoid lose and quality accident |