NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

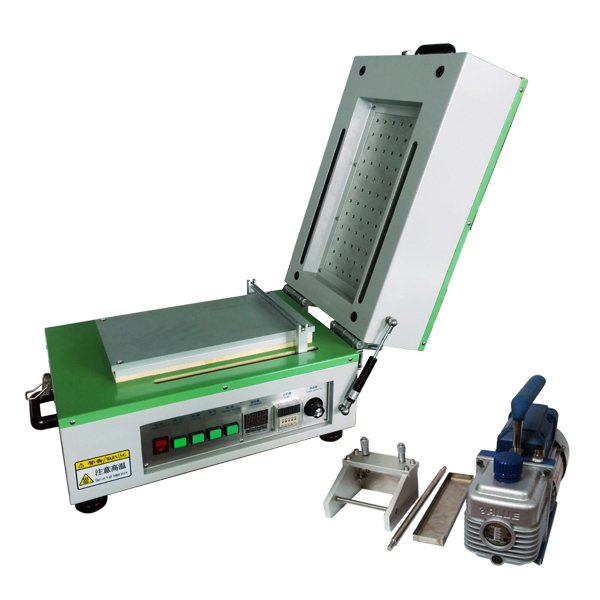

Battery machine Coin cell punching machine / button cell disc cutting machine /Compact Precision Disc Cutter YD-0124

- Product description: Battery machine Coin cell punching machine / button cell disc cutting machine /Compact Precision Disc Cutter YD-0124

Product introduction

|

Picture |

|

|

Introduction |

This machine is mainly used in die cutting process. It applied to 0.005~0.5 thickness cathode/anode, separator for die cutting. |

|

Main feature |

- Up die mould adopts high precision guide rail, High precision punching, no burr, indentation. - The die cutting thickness range: 0.005~0.5mm a wide variety of battery material - Small volume, Easy to operate, flexible and quick to use - The appearance is exquisite, beautiful, simple, clean and easy to maintain and has the advantages of small size and so on. - Material: aluminum alloy corrosion resistant material, never rust |

|

Specification |

- Die cutting dimension: optional Ф3mm~Ф24mm customized; - Die cutting trip: 25mm; - Dimension:L110×W150×H235mm;(4.3in×5.9in×9.3in) - Can be transferred through glove box antechamber with overΦ200mm diameter - Material: aluminum alloy, rust proof; - Weight:6Kg; |

|

Mould |

Options mould size:Ф3~Ф24mm customized |

|

Maintenance method and attention |

- Clean with clean rag dipped in alcohol after each using and if no use the next day,coated anti rust oil。 - Clean the guide rails and other moving parts regularly, and add oil for moving smoothly. - Regular inspect various parts of machine drawing screw, the nut, pin and other fasteners, prevent loosening, eliminate punching machine quality accidents and related accidents. |