NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

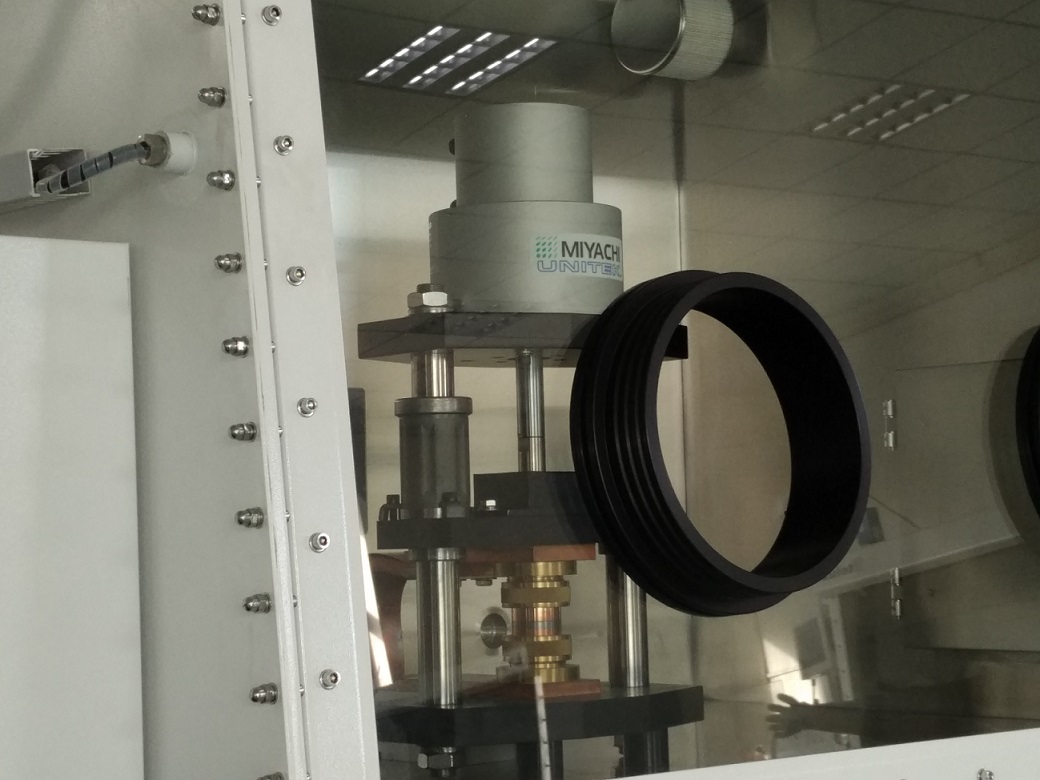

-65℃ Dew point,ETS1200 Advanced Glovebox Welding System,Electronic Packages Gloveboxes,Custom Heating Process,200°C Oven

- Product description: -65℃ Dew point,ETS1200 Advanced Glovebox Welding System,Electronic Packages Gloveboxes,Custom Heating Process,200°C Oven

Product introduction

Key Features

|

Leak Rate |

< 0.05vol%h |

|

Dew point |

< 65℃ |

|

Oxygen |

< 1ppm |

|

Enclosure Size (W x D Floor / D top x H) |

47.5 in x 29.5 in / 25.5 in x 35.5 in (1200 mm x 750 mm / 650 mm x 900 mm) - 2 Glove Ports |

|

|

59 in x 29.5 in / 25.5 in x 35.56 in (1500 mm x 750 mm / 650 mm x 900 mm) - 3 or 4 Glove Ports |

|

Antechamber and Oven Sizes (L x W x H) |

13.8 in x 11.8 in x 11.8 in (350 mm x 300 mm x 300 mm) - Stainless Steel |

|

|

13.8 in x 11.8 in x 11.8 in (350 mm x 300 mm x 300 mm) - Stainless Steel |

|

Antechamber Controls |

HMI: Backfill |

|

Oven Controls |

HMI: Temperature, Vacuum, Backfill |

|

Antechamber & Oven Interlocks |

Yes |

|

Antechamber & Automated Sliding Inner Door |

Yes |

|

Antechamber and Oven Door Loading Options |

Front, Rear, End |

|

Oven Heating Configuration |

Heated Shelves |

|

|

4 Floors (3rd floor workspace) |

|

Bakeout Oven Temperature |

200°C |

|

|

Optional 300°C |

|

Historical Data Collection |

Usb Stick Export |

|

Purification system |

One Column (Optional Double column) |

|

Vacuum pump |

nXDS10i (One or two) |

|

Input Power |

220 VAC, 10 A |

|

Single or 3 Phase |

2 Phase |

|

Input Gas |

72.5 psi minimum (5.0bars) |

|

Weight |

Varies with selected options |